Liquid Heat Transfer in a Plate & Shell Heat Exchanger (PSHE)

Efficient heat transfer begins with a clear understanding of how heat is transferred from a flowing liquid to the heat-transfer surface. In all plate-type heat exchangers, liquid-side heat transfer at the plate surface is the foundation of thermal performance.

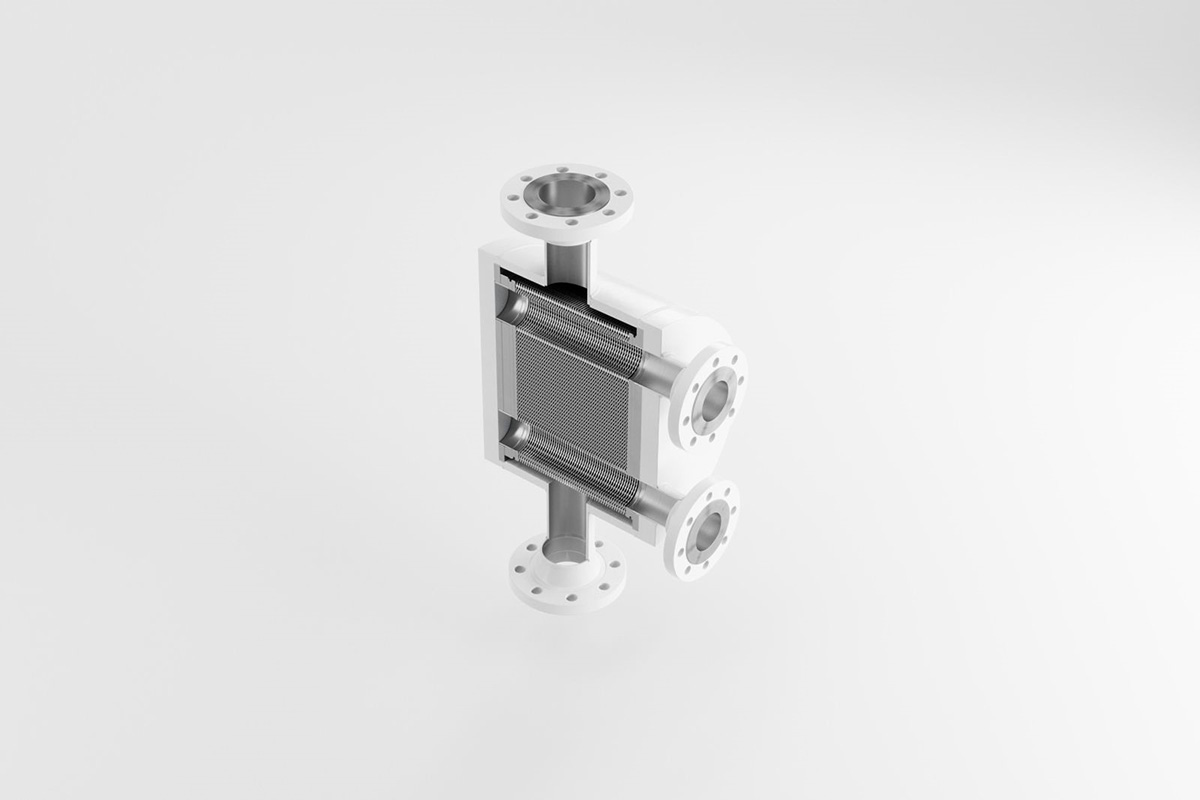

In the JINCHEN Plate & Shell Heat Exchanger (PSHE), liquids can be heated or cooled with exceptional efficiency. Depending on process requirements, the liquid can flow either on the plate side or the shell side of the exchanger. Plate size, corrugation pattern, and channel geometry are then carefully selected to match the specific operating conditions.

For liquid heat transfer, it is essential to avoid laminar flow and instead promote turbulent flow patterns. Turbulence enhances mixing near the plate surface, significantly improving heat transfer between the flowing medium and the heat-transfer plates. As a plate-type heat exchanger, the PSHE inherently provides superior heat-transfer performance compared with tube-type exchangers.

In addition to high thermal efficiency, the JINCHEN PSHE offers maximum operational safety. Its fully welded construction eliminates the risk of leakage, making it a reliable and secure solution for liquid heating and cooling applications.

JINCHEN has thousands of liquid heaters and coolers operating worldwide in applications such as water heating, crude oil cooling, and pigment or color paste processing, among many others.

Typical Liquid Applications