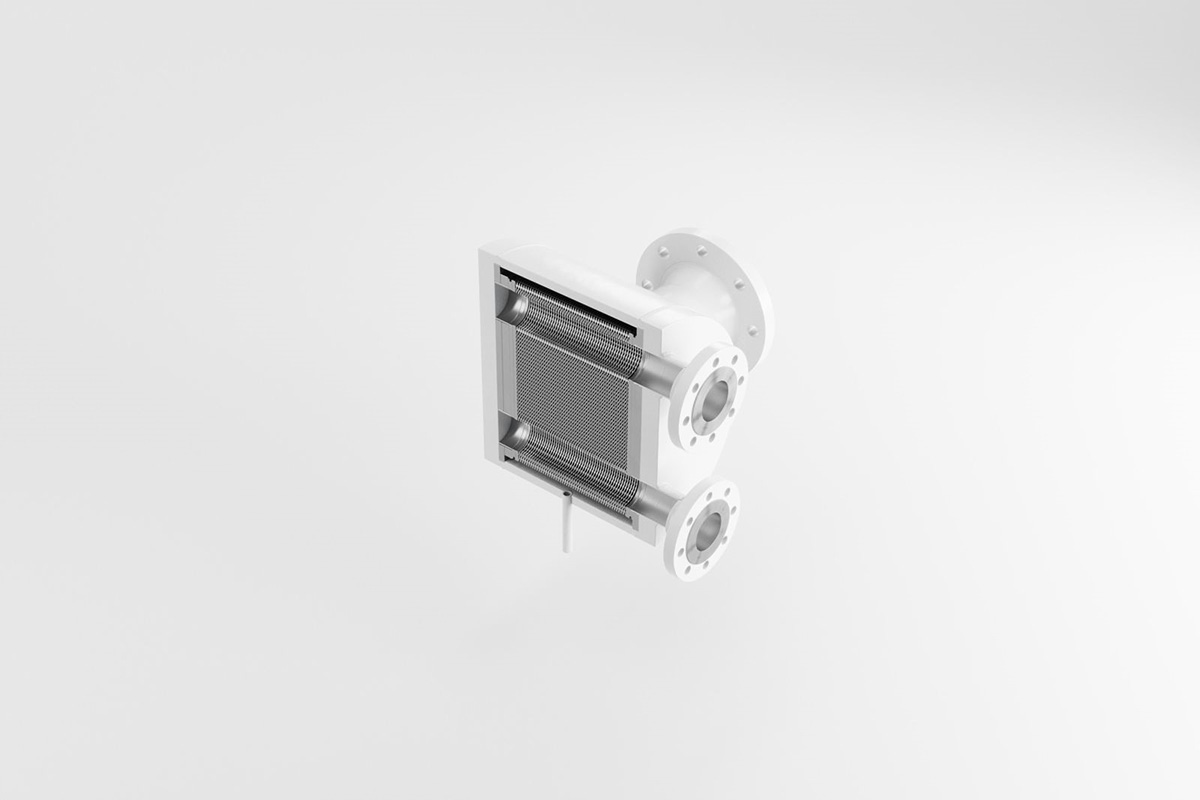

Gas Heat Transfer in a Plate & Shell Heat Exchanger (PSHE)

Gas heat transfer can be handled efficiently with JINCHEN Plate & Shell Heat Exchangers (PSHE). Compared with tube-type heat exchangers, heat-transfer plates provide significantly higher thermal efficiency, making PSHE a highly effective solution for gas applications.

The key challenge in gas heat transfer lies in the relatively low thermal conductivity and heat capacity of gases compared to liquids. As a result, gas applications typically involve much larger volumetric flow rates. The JINCHEN Plate & Shell Heat Exchanger is uniquely suited to these demanding conditions, as its design can be fully optimized to accommodate high gas volumes and low heat-transfer coefficients.

In most gas applications, the gas stream is arranged on the shell side of the PSHE. This configuration allows the use of large-diameter shell-side nozzles, specifically designed to handle high-volume gas flows. Shell-side connections can be positioned freely around the shell circumference, and the orientation and angle of the plate pack inside the shell can be adjusted to achieve the optimal corrugation angle and flow distribution for gas heat transfer.

To further enhance performance in gas duties, JINCHEN PSHE 5SH has been specifically developed for gas applications, offering optimized geometry and flow arrangements tailored to gas-side heat transfer requirements.

Typical Gas Applications