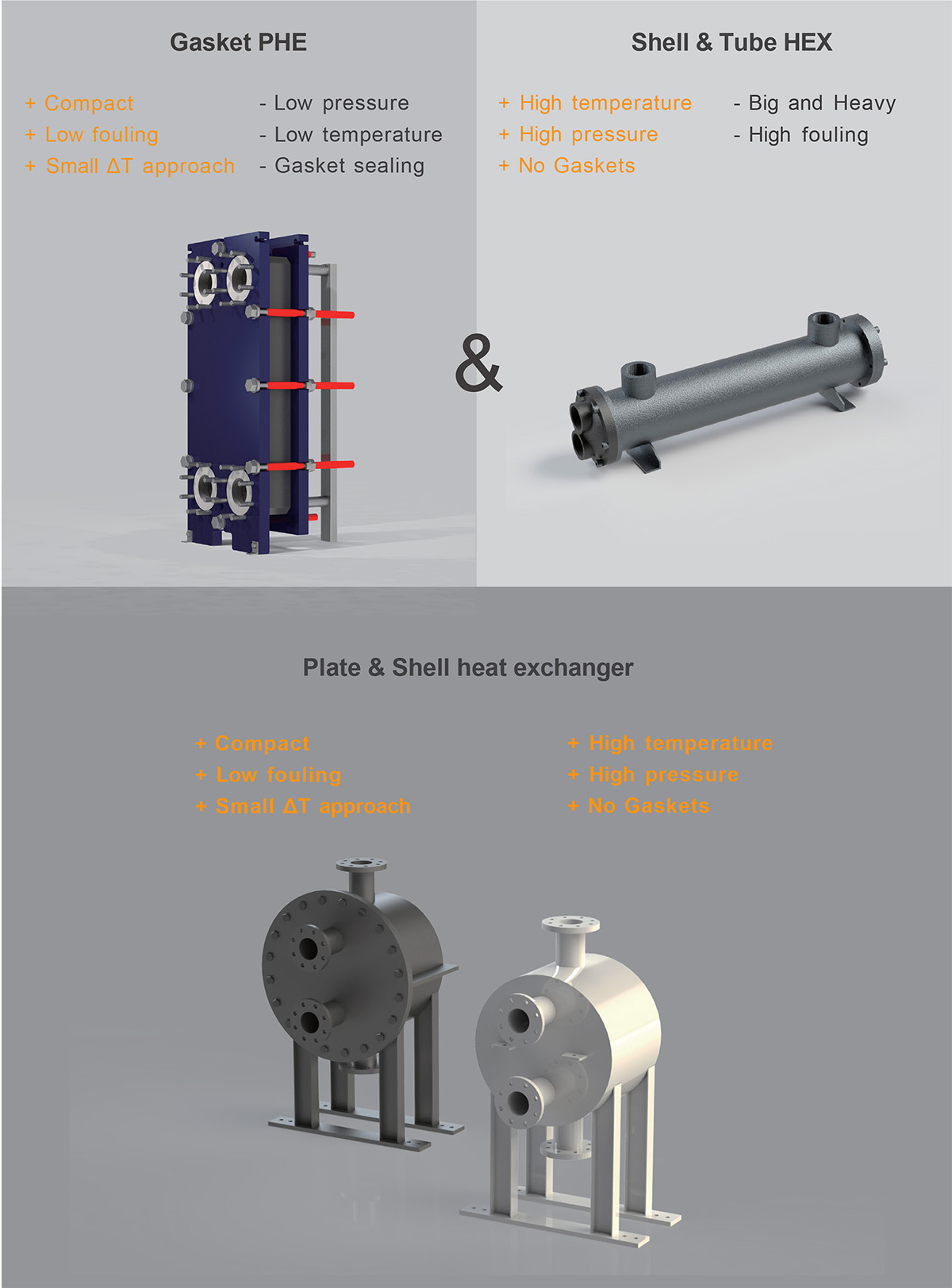

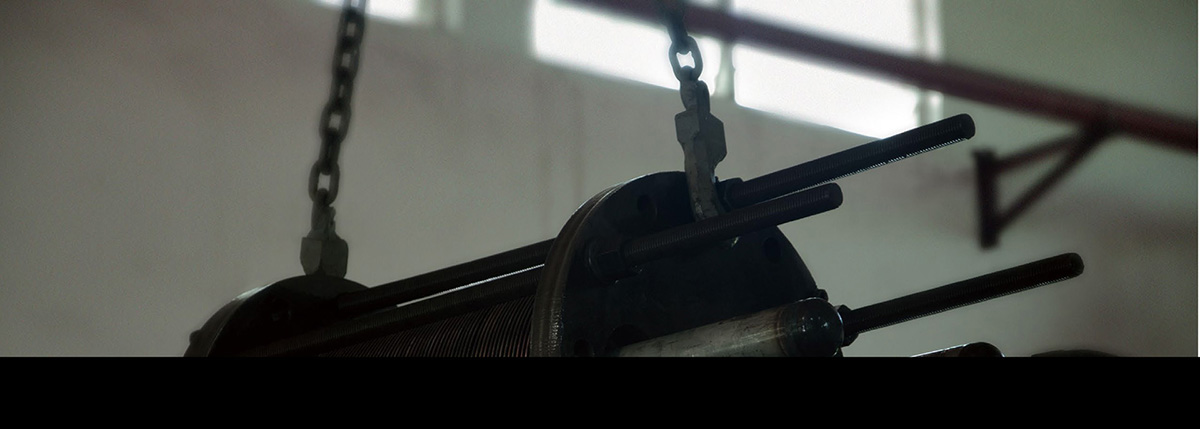

The PSHE range of heat exchangers are new generation heat exchangers, combining the best properties of the

Plate & Frame and Shell & Tube heat exchangers. The PSHE provides high heat transfer rates with a high

pressure and temperature operating range. They have no gaskets, are compact, low fouling and can operate at

close approach temperatures.

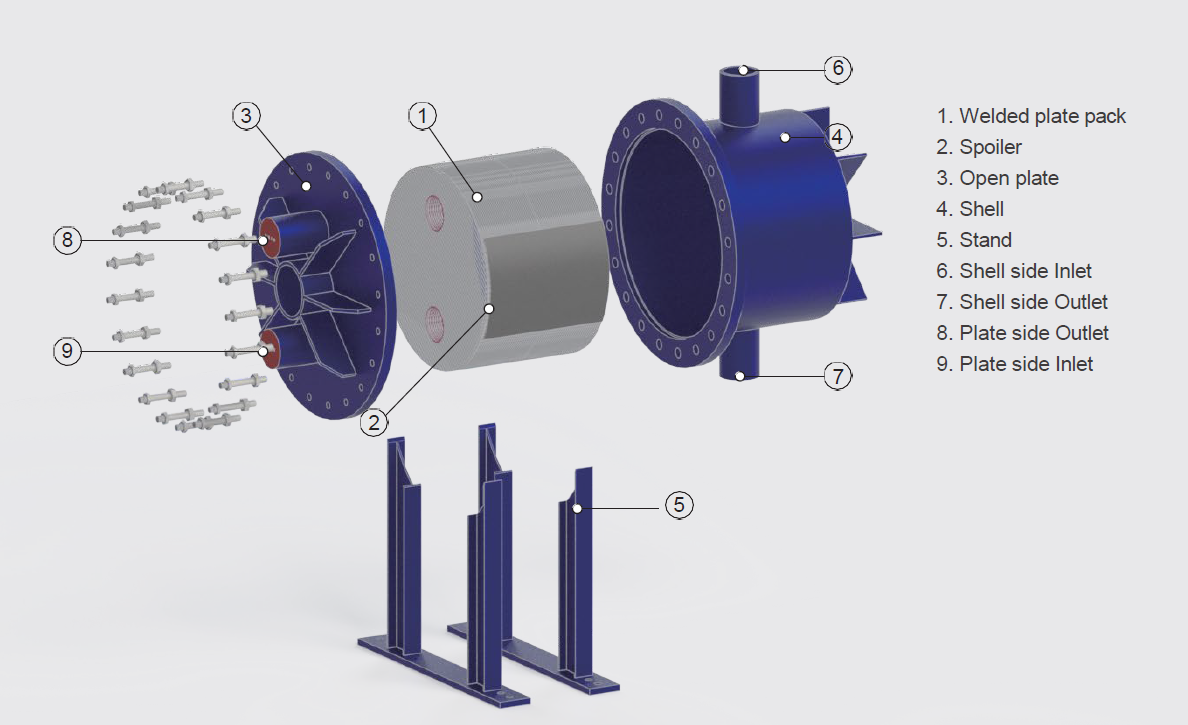

At the heart of the PSHE is a fully welded pack of circular plates without gaskets. This plate pack is housed within a tubular shell to provide a strong compact construction.

The PSHE series have a very wide operating range with capacities of up to 100 MW / units, and can operate at pressures up to 100 bar and temperatures up to 400°C.

They have a low maintenance design that provides

flexibility to select different material and nozzle combina-tions.

Benifits:

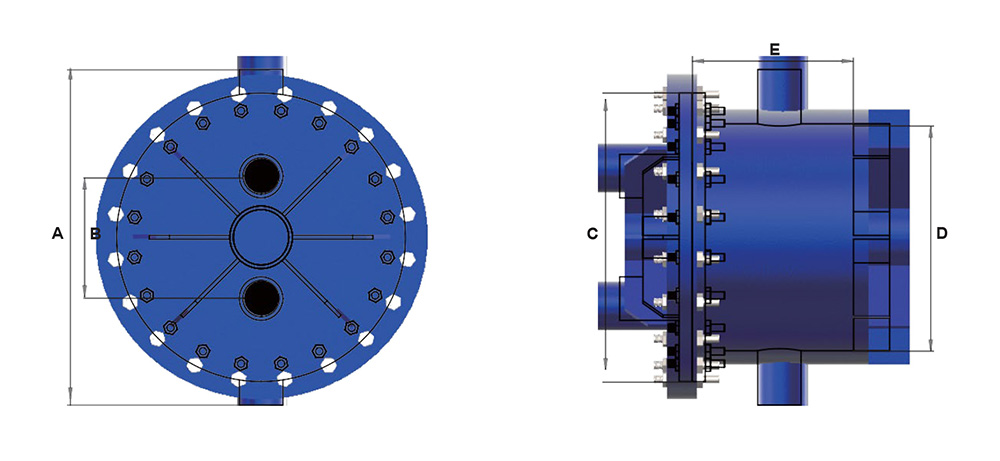

**Dimensions in mm

Model |

A |

B |

C |

D |

E |

Plates side port |

Shell side port |

BPS16 |

240 |

98 |

250 |

168 |

2.4*N+2 |

DN15 |

DN15-DN80 |

BPS22 |

448 |

135 |

310 |

219 |

2.4*N+3 |

DN20 |

DN20-DN100 |

BPS46 |

469 |

174 |

368 |

269 |

2.4*N+4 |

DN40 |

DN25-DN200 |

BPS72 |

565 |

277 |

460 |

355 |

2.8*N+4 |

DN50 |

DN25-DN300 |

BPS128 |

600 |

298 |

694 |

464 |

2.8*N+6 |

DN80 |

DN25-DN350 |

BPS179 |

963 |

338 |

725 |

559 |

2.8*N+6 |

DN100 |

DN25-DN400 |

BPS647 |

1520 |

650 |

1250 |

1016 |

3.2*N+6 |

DN150 |

DN25-DN700 |

BPS1200 |

1828 |

900 |

1548 |

1372 |

3.2*N+8 |

DN300 |

DN25-DN1000 |

BPS1600 |

2098 |

1000 |

1838 |

1562 |

3.2*N+8 |

DN350 |

DN25-DN1200 |

Shell |

Plates |