What Is the JINCHENG Plate & Shell Heat Exchanger?

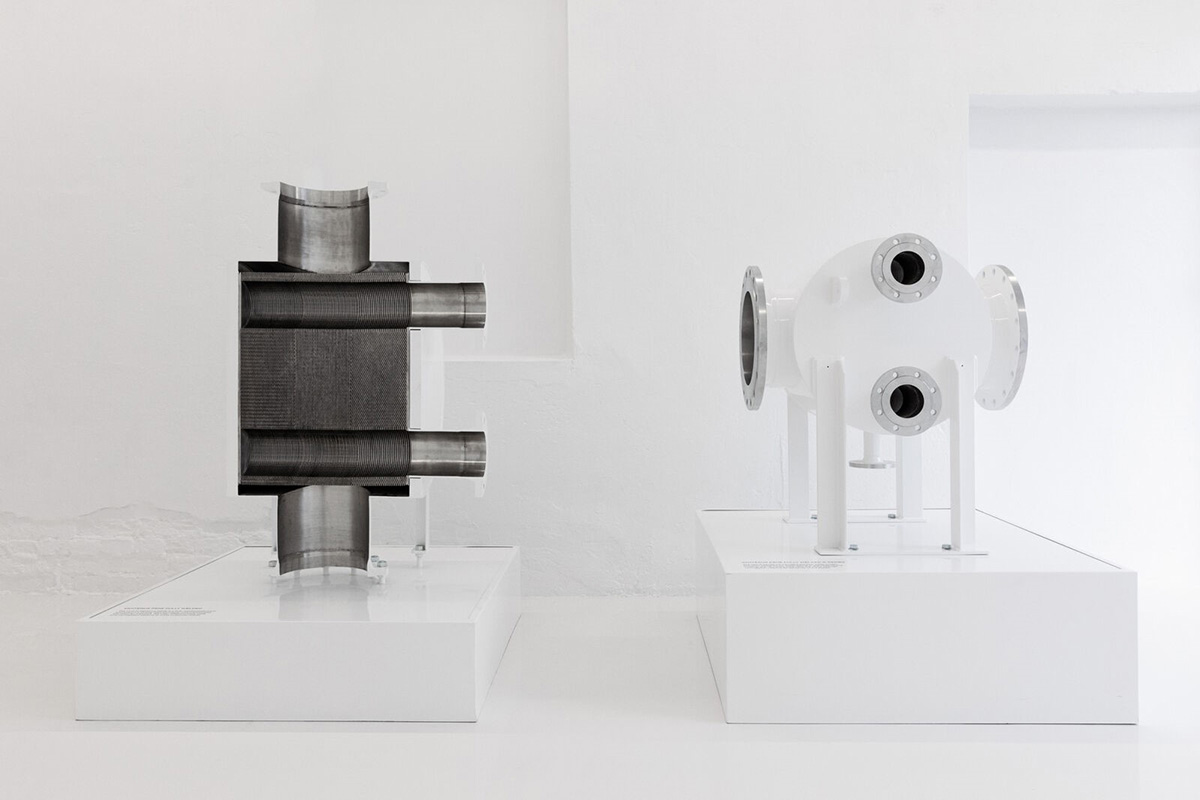

The Jinchen Plate & Shell Heat Exchanger (PSHE) represents a leading advancement in heat-exchanger technology. Its core consists of a fully welded plate pack housed within a robust shell, completely eliminating the need for gaskets. This innovative design allows the PSHE to combine the high thermal efficiency of Plate & Frame heat exchangers with the mechanical strength and pressure resistance of Shell & Tube units.

Compared with conventional heat exchangers, the PSHE offers numerous advantages. Its compact and lightweight construction reduces footprint and installation requirements. The gasket-free, all-welded design enables operation under higher pressures and temperatures than traditional Plate & Frame exchangers. In addition, the rigid shell structure ensures excellent durability, straightforward maintenance, and high energy efficiency, making the PSHE a reliable solution for demanding industrial applications.

Why Choose the JINCHEN Plate & Shell Heat Exchanger?

More than 30 years ago, Plate & Shell Heat Exchanger (PSHE) technology was introduced to redefine industry standards. Today, it stands as a benchmark for durability, efficiency, and future-ready performance. While others follow established paths, JINCHEN continues to lead—driven by patented innovation, proven field performance, and solutions engineered to support the next generation of energy systems.

PSHE technology was developed because conventional solutions no longer met modern demands. The JINCHEN Plate & Shell Heat Exchanger, based on patented design principles, brings together the best of both worlds: the exceptional heat-transfer efficiency of plate heat exchangers and the mechanical strength and high-pressure capability of shell-and-tube designs.

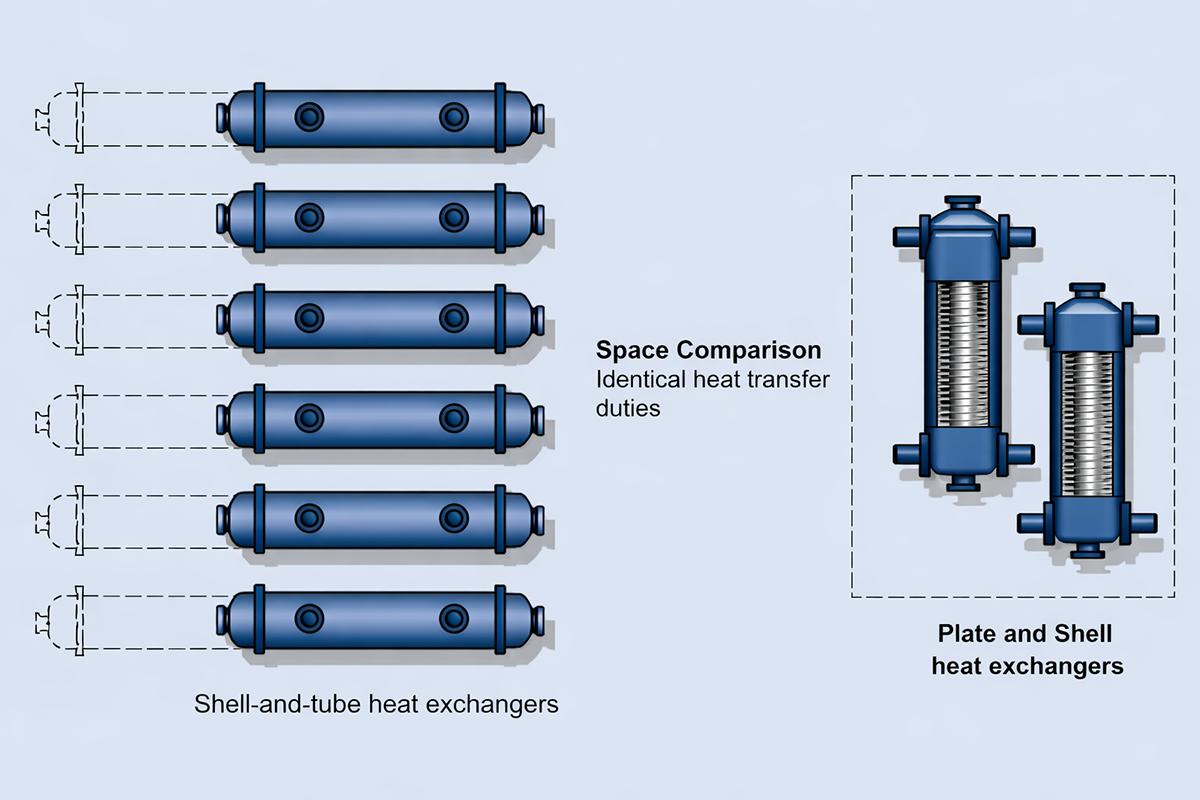

Compared with traditional shell-and-tube heat exchangers, the JINCHEN PSHE offers clear advantages. Its compact and energy-efficient design is purpose-built for today’s energy challenges. With rapid response to load changes, up to 70% smaller footprint, flexible flow configurations, and precise temperature control, the JINCHEN PSHE is a smarter, more efficient alternative to conventional shell-and-tube heat exchangers.

Compared with traditional plate heat exchangers, the JINCHEN Plate & Shell Heat Exchanger delivers superior resistance to pressure, temperature, and aggressive media. Its robust, fully welded construction ensures reliable, high-quality performance with enhanced safety and a significantly reduced risk of leakage—making it a stronger and more dependable solution than conventional gasketed plate heat exchangers.

Designed for the Next Generation

The fully welded, gasket-free design eliminates common failure points, minimizes downtime, and enhances thermal performance. Just as importantly in today’s industrial landscape, it reduces installation footprint by up to 70% compared with conventional heat exchanger technologies.

No leaks. No plate re-tightening. No compromises.

Only long-term, reliable performance—engineered to operate efficiently for decades. The JINCHEN Plate & Shell Heat Exchanger represents a sustainable heat-transfer solution, purpose-built for the next generation of energy and process applications.

PSHE Construction

The fundamental function of a heat exchanger is to transfer heat from the primary side to the secondary side through heat-transfer plates that separate the two media. JINCHEN Plate & Shell Heat Exchangers are widely applied in heating, cooling, condensing, evaporating, and process heat recovery duties.

The exchanger consists of a fully welded pack of circular heat-transfer plates installed inside a cylindrical steel shell—hence the name Plate & Shell Heat Exchanger. This construction creates short, highly efficient flow paths while maintaining a low pressure drop. As a result, the PSHE is particularly well suited for applications involving viscous or demanding process fluids. The absence of gaskets and the use of fully welded connections ensure high integrity and long-term operational reliability.

Thanks to this unique design, JINCHEN Plate & Shell Heat Exchangers are capable of meeting extremely demanding design conditions.

Mechanical Design Range

All JINCHEN heat exchangers are designed and manufactured in accordance with applicable international design codes, including but not limited to:

Design Codes

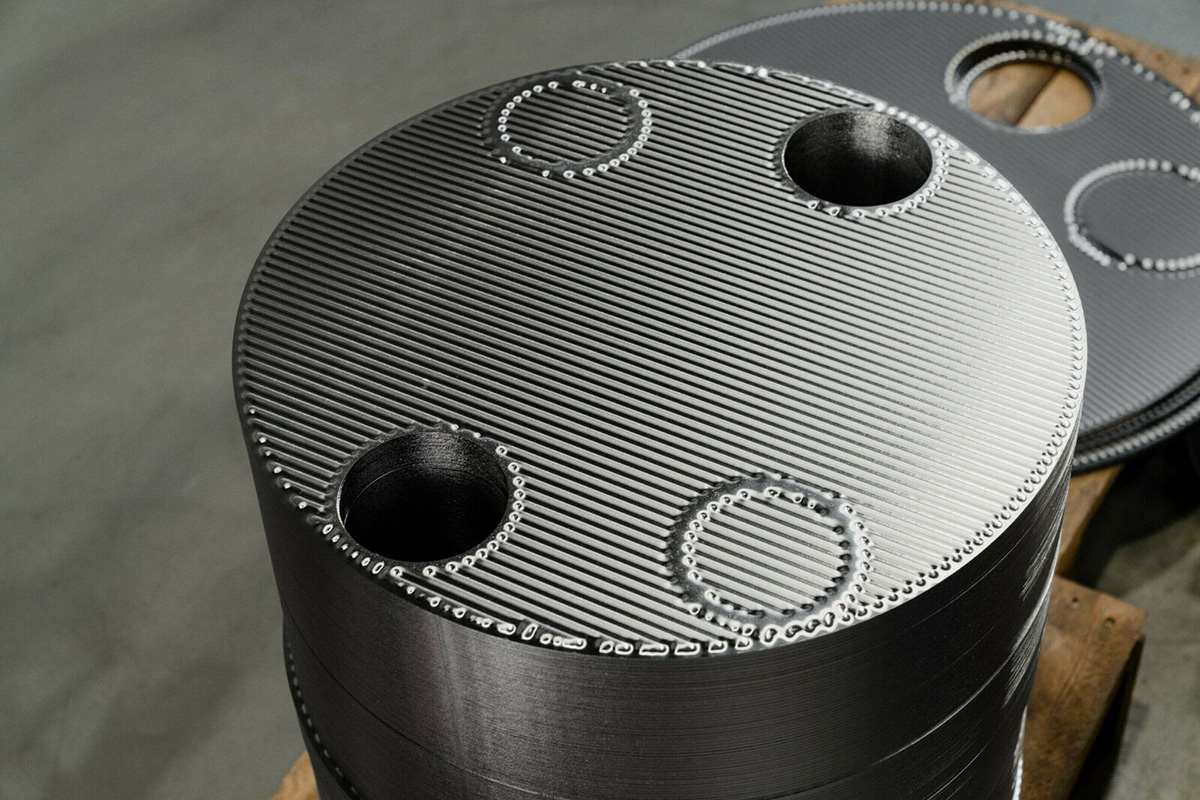

Plate Pack

The standard configuration of the JINCHEN Plate & Shell Heat Exchanger features a stainless-steel plate pack combined with a carbon steel or stainless-steel shell. Depending on process requirements, alternative materials can also be selected to suit specific media, temperatures, or corrosion conditions.

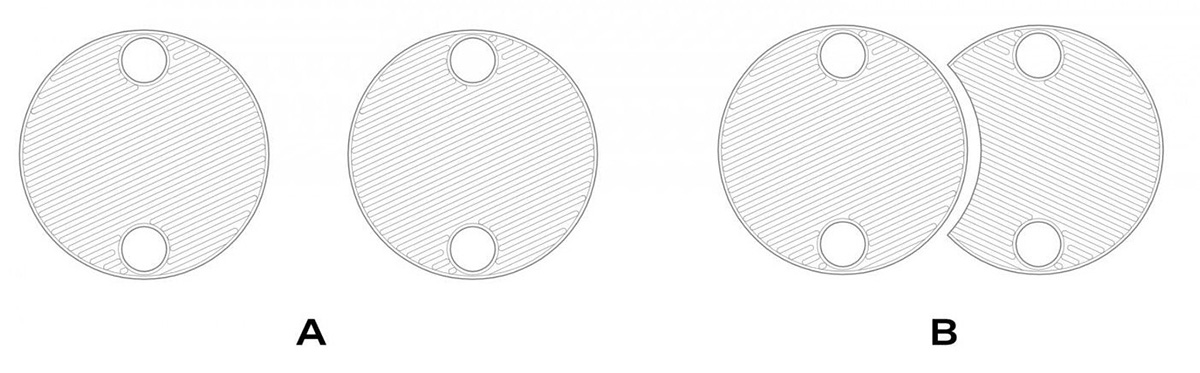

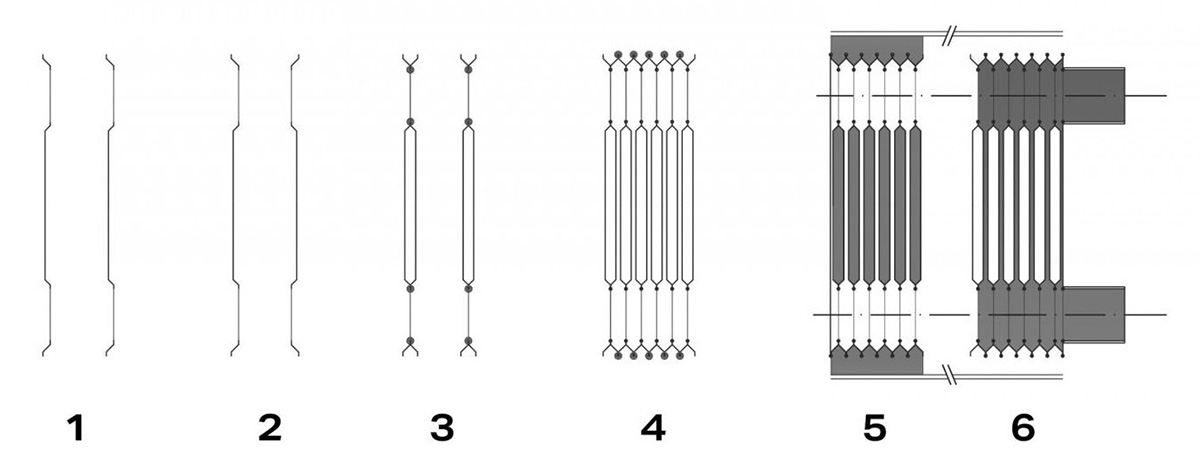

The figures below illustrate the basic assembly concept of the plate pack.

Plate production (A = pressed plates with corrugation; B = one plate turned 180° and moved behind the other)

Plate pack assembly (1 = plates (see A above); 2 = one plate turned 180° (see B above); 3 = plate pair assembling (welding holes); 4 = plate pack assembling (outside welding); 5 = shell side flow; 6 = plate side flow)

Materials

The materials used in the plate pack can be selected to meet specific customer and process requirements. JINCHEN has extensive experience working with a wide range of metallic materials, and new materials are continuously evaluated through ongoing testing programs. If the required material is not listed below, please contact JINCHEN for further assessment.

Plate Materials

Shell

The shell, functioning as the pressure vessel, encloses and protects the plate pack while directing the shell-side flow through the exchanger. Its design can be optimized to meet specific operating conditions such as pressure, temperature, and flow distribution.

JINCHEN shell design follows the requirements of the applicable design code—typically PED (2014/68/EU) or ASME Section VIII, Division 1.

Shell dimensions, materials, and nozzle configurations can be fully customized to suit individual process requirements.

Typical Shell Materials

PSHE – A Fully Customised Solution

Every JINCHEN Plate & Shell Heat Exchanger is individually engineered to meet the specific requirements of each customer’s process. The design process begins with a detailed thermal calculation to determine the required heat-transfer surface area, which is then integrated with a tailored shell design.

This represents a key distinction between JINCHEN Plate & Shell Heat Exchangers and conventional plate heat exchangers: the shell design is not fixed. Instead, it is fully adjustable, allowing the exchanger to be precisely configured to match process demands.

The position of the plate pack within the shell can be modified, for example, to provide additional volume for evaporating gases. Large shell-side nozzles can also be incorporated to accommodate high-volume gas flows. In condenser applications, a condensate receiver can be integrated directly into the shell or supplied as a separate vessel, complete with the required service connections.

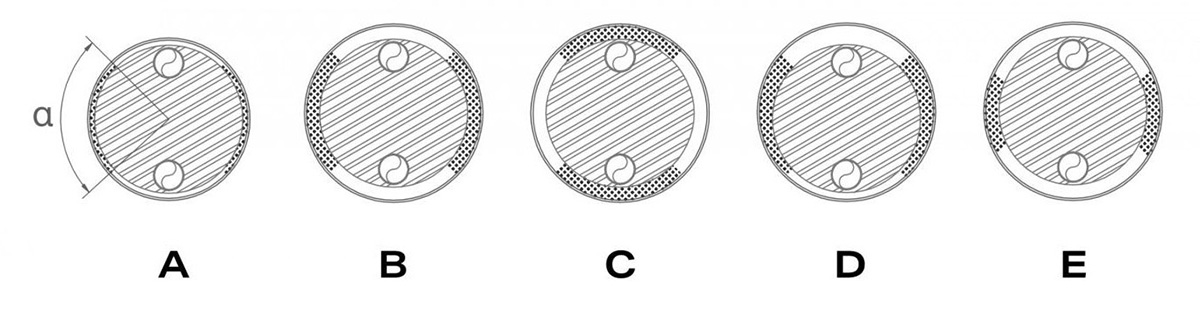

Flow Director Options

Flow directors are used to create optimal flow distribution through the plate pack. The standard axial flow-director angle (α) is 90°. In condenser applications, a 45° angle is typically applied as a standard solution. For certain applications—such as low pressure-drop (Δp) duties—angles smaller than 90° may be beneficial.

In some cases, flow directors are not required at all, for example in kettle-type evaporators. For unit type C configurations, the flow directors are rotated by 90° to achieve the desired flow pattern.

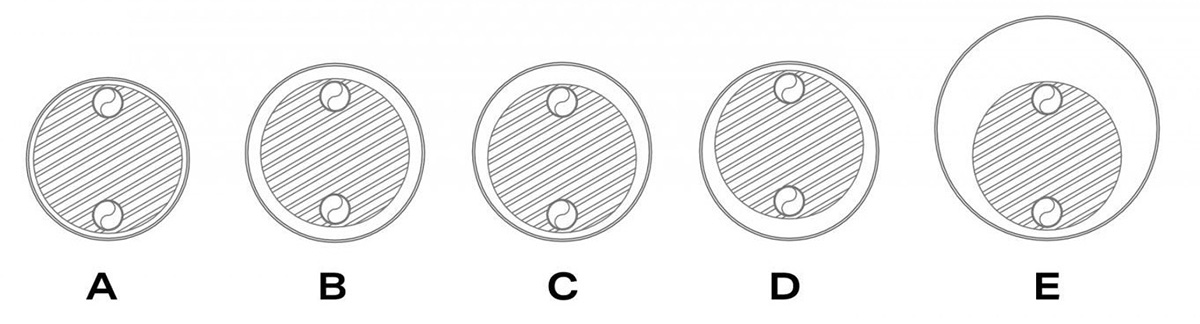

Plate Pack Orientation in the Shell

Different plate pack orientations can be applied to suit specific operating conditions:

A – Standard shell, concentric plate pack; general applications

B – Enlarged shell, concentric plate pack; gas applications

C – Enlarged shell, eccentric to bottom; flooded evaporators

D – Enlarged shell, eccentric to top; condensers with integrated receiver

E – Oversized shell, eccentric to bottom; combined evaporator applications

Pre-Selected Designs

In addition to fully customized solutions, JINCHEN also offers a range of pre-engineered designs to shorten the design phase and reduce delivery times. These solutions can be applied directly or used as a basis for further customization.

Heat Transfer in Plate Heat Exchangers

Heat transfer is the core function of any heat exchanger. Its design is governed by the fundamental laws of thermodynamics:

First Law of Thermodynamics

Energy cannot be created or destroyed. In a heat exchanger, the heat lost by the hot side is equal to the heat gained by the cold side.

Second Law of Thermodynamics

Heat naturally flows from a higher-temperature medium to a lower-temperature medium in order to reduce the temperature difference.

Heat transfer is the exchange of thermal energy between hot and cold bodies and occurs through three basic mechanisms:

In heat exchangers, heat transfer is achieved primarily through a combination of conduction and convection, both of which are evaluated in thermal design calculations.

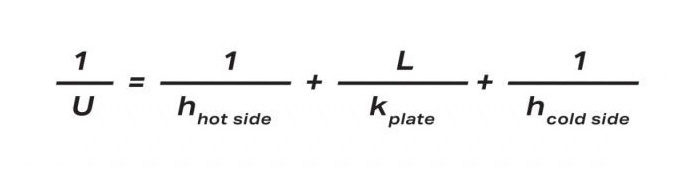

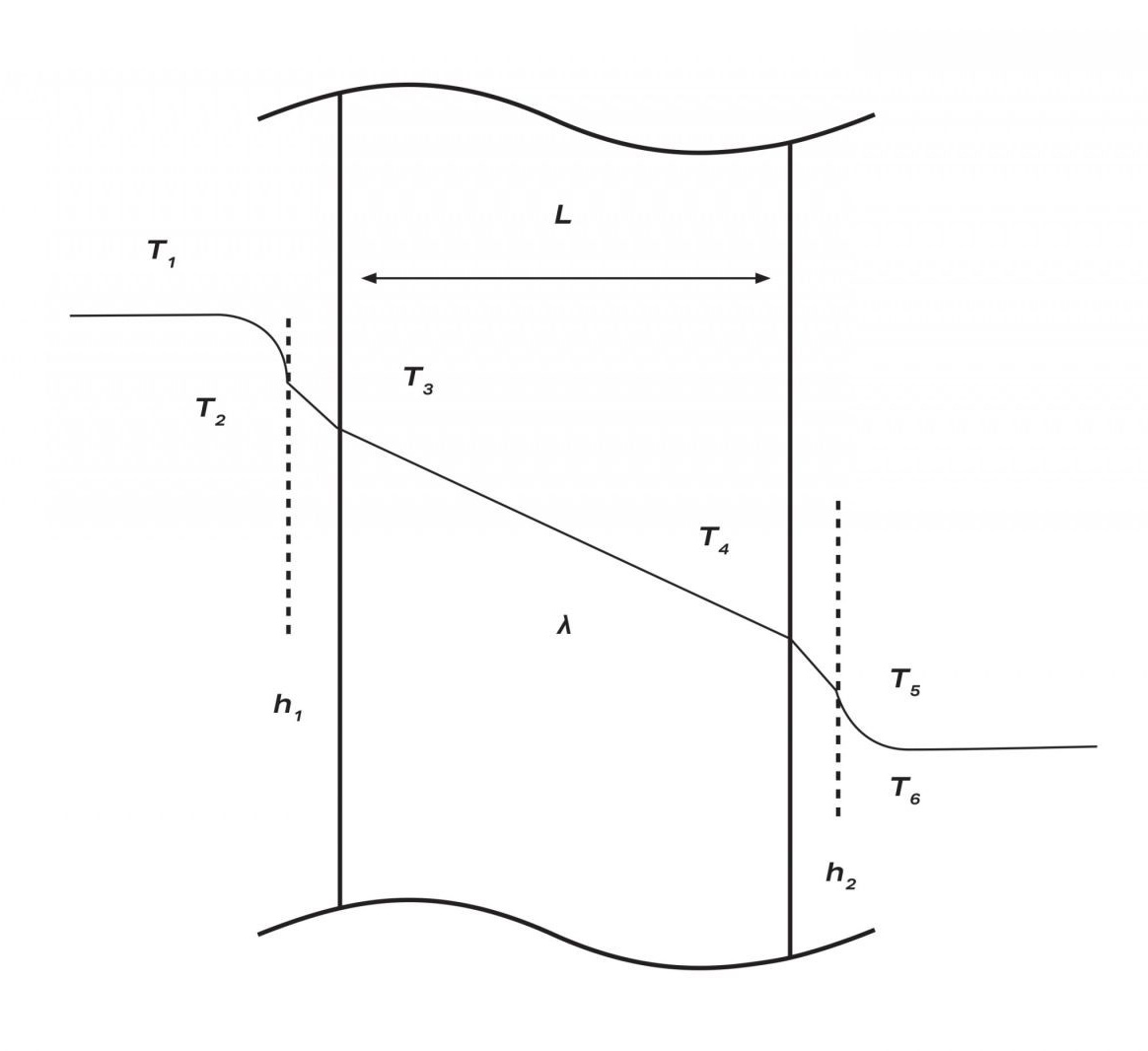

Calculating Heat Transfer

The overall heat-transfer coefficient U is determined by the combined effect of convective heat transfer on both sides of the heat-transfer surface (h_hot and h_cold) and thermal conduction (k) through the heat-transfer plate.

Thermal conduction depends on the material conductivity and thickness of the plate. Plate materials are typically stainless steel, with thicknesses ranging from 0.7 mm to 1.5 mm. While thinner plates enhance conductive heat transfer, plate conduction up to approximately 1.0 mm thickness generally has a minor influence compared to the total heat-transfer performance.

The dominant contribution comes from convective heat transfer—the transfer of heat between the plate surface and the flowing fluid. Convection occurs as heat is carried by fluid motion and is represented by the heat-transfer coefficient h.

Convective heat transfer is the most complex parameter to calculate. Different calculation methods apply depending on geometry and operating conditions, such as liquid flow, gas flow, condensation, or evaporation. Classical correlations (e.g., Dittus–Boelter) are validated and refined through experimental testing across various heat-exchanger designs.

Because convection is the dominant heat-transfer mechanism in plate heat exchangers, enhancing convective effects is critical to achieving high thermal performance.

The convective heat-transfer coefficient is influenced by fluid properties and the geometry of the heat-transfer surface. While fluid properties are usually fixed by the process, the exchanger design and structure can be optimized to maximize heat-transfer efficiency.

Why Heat Transfer Is Superior in JINCHEN Plate & Shell Heat Exchangers

(Compared with Shell & Tube Heat Exchangers)

The use of heat-transfer plates instead of tubes significantly increases the effective heat-transfer surface area. In addition, the plate geometry creates flow paths that promote higher turbulence even at relatively low flow velocities.

Flow between plates experiences frequent boundary-layer reattachment compared to pipe flow. This means the fluid does not move smoothly along the surface; instead, the flow direction continuously changes, disrupting the thermal boundary layer and enhancing heat transfer. This phenomenon explains the substantially higher heat-transfer coefficients achieved by Plate & Shell Heat Exchangers.

As a result of this highly efficient heat-transfer mechanism, JINCHEN Plate & Shell Heat Exchangers are typically 60–70% more compact than conventional Shell & Tube heat exchangers while delivering the same thermal duty.

Fully Welded Plate Heat Exchanger (PSHE)

The JINCHEN Plate & Shell Heat Exchanger (PSHE) is a fully welded plate heat exchanger. The heat-transfer plates are welded together without the use of external gaskets. While gasketed plate heat exchangers are suitable for many standard applications, their operating range is limited by temperature and pressure, and they inherently carry the risk of gasket failure or media permeation. Similar limitations also apply to semi-welded plate heat exchangers.

With the JINCHEN PSHE, all gasket-related risks are completely eliminated.

The plate pack inside the PSHE consists of a series of circular heat-transfer plates, fully welded together along both the plate periphery and the port openings. This creates a compact, pressure-resistant plate assembly with exceptional mechanical integrity.

The fully welded plate pack is housed within a cylindrical pressure vessel, combining maximum operational safety with outstanding thermal performance—without compromise.

All plate welding is performed using fully automated welding lines, allowing precise control and continuous monitoring of weld quality throughout the manufacturing process. This ensures consistent performance, long service life, and the highest reliability in demanding industrial applications.

Fouling

What Is Fouling?

Fouling refers to the accumulation of unwanted deposits on heat-transfer surfaces, which reduces heat-transfer efficiency. As fouling develops, pressure drop increases and energy consumption rises. In severe cases, excessive fouling can cause mechanical damage to the heat exchanger and may ultimately lead to equipment failure.

Fouling can often be minimized—or even eliminated—when properly addressed during the design phase. Effective fouling mitigation starts with understanding the underlying fouling mechanisms, which are commonly classified into six main categories:

Fouling Mitigation

The most effective way to mitigate fouling is through optimized heat-exchanger design. JINCHEN’s extensive experience with fouling phenomena, combined with advanced heat-exchanger engineering, allows fouling risks to be significantly reduced—often without the need for frequent cleaning.

JINCHEN Plate & Shell Heat Exchangers can be configured with different plate corrugation angles and plate gap sizes, helping to prevent clogging caused by suspended solids or contaminants.

More importantly, proper control of flow behavior between the plates is critical to preventing fouling attachment on heat-transfer surfaces. High fluid velocity near the plate surface not only enhances heat transfer, but also mitigates fouling by generating high shear stress. Shear stress is a function of pressure drop and heat-exchanger geometry.

What If Cleaning Is Required?

In some applications, even well-designed heat exchangers cannot completely prevent fouling. In such cases, an effective and economical cleaning strategy becomes essential.

The most suitable cleaning method is selected based on the type of fouling and the heat-exchanger design. JINCHEN Service provides a range of cleaning solutions and performance inspections for existing heat exchangers. Cleaning and testing can be carried out either at JINCHEN facilities or directly on site, depending on customer requirements.